Material Composition and Characteristics

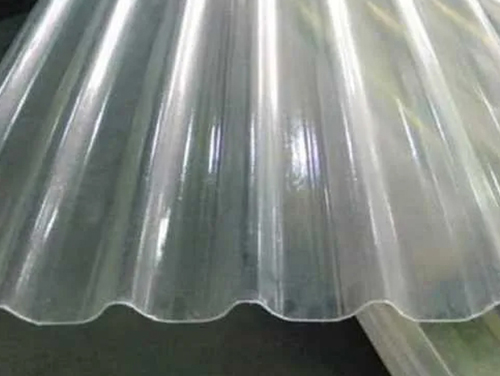

Fiberglass Reinforced Plastic (FRP) belong to the polyester resin family and are reinforced with fiberglass, creating flexible plastic panels. They are non-conductive, making them safe from electrical currents and impact-resistant. FRP is stronger than many types of steel in the lengthwise direction and significantly lighter than steel.

Applications and Benefits

FRP is ideal for roofing because it allows uniform, diffused light to pass through. It is corrosion-resistant and provides protection from wear and tear, as well as surface damage. The chemical composition of FRP makes it UV resistant, smoke, and fire retardant. These panels are used for both walls and ceilings and can be directly installed over drywall, wood, or other solid surfaces. FRP is extremely durable and long-lasting, making it cost-efficient due to reduced need for replacements. The panels' water-resistance capabilities make them suitable for areas prone to rainfall, offering a universal roofing solution.

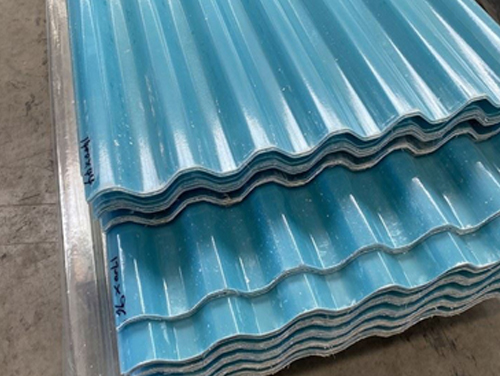

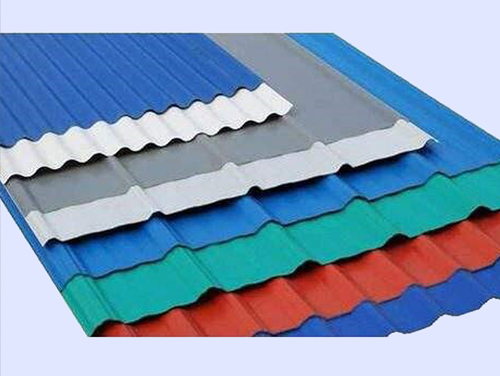

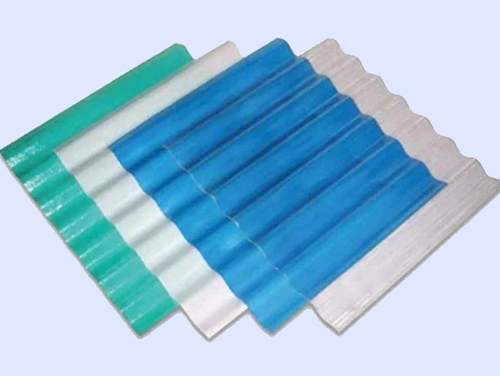

Variety and Customization

Fiberglass reinforced panels are manufactured in various sizes and types to meet customer requirements. They are eco-friendly and environmentally safe, contributing to sustainability.

Ease of Installation

Installing FRP is straightforward: simply apply adhesive and paste the panel onto the surface. This simplicity makes it an attractive option for both professional and DIY projects.

| Type | GI/AC Profile/TATA Naali/Plain Roll | |

|---|---|---|

| Colour | Clear, Opal white, Milky, Smoke, Black, Green, Blue, Red etc. | |

| Thickness Range | 1.0 mm – 3.5 mm | |

| Dimension | 2440*1220 mm, 1830*1220 mm, 1220*915 mm, and other as customized | |

| Surface Protection | Masking Brown Paper / PE Film | |